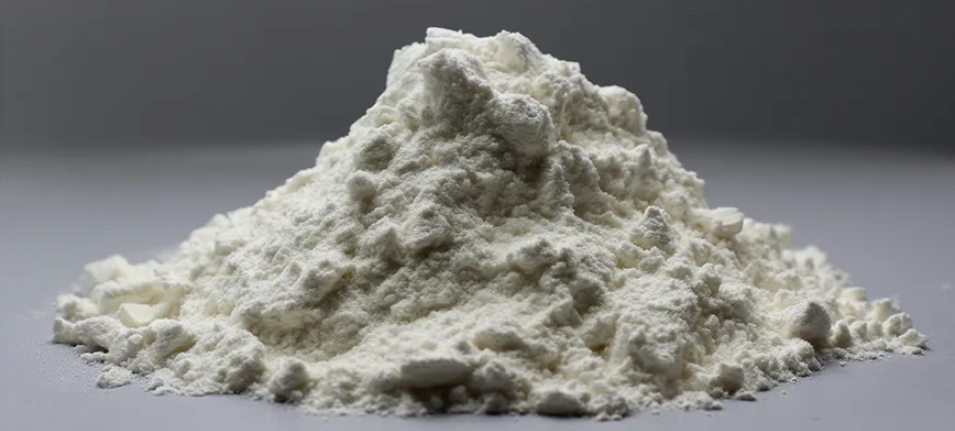

In water-based coating systems, thickeners are key materials that affect the fluidity, storage stability, and application performance of coatings. Hydroxyethyl cellulose (HEC), with its excellent thickening properties, solubility, and rheological control capabilities, is widely used in many industries, including latex paints, exterior wall coatings, putties, and adhesives. So, how exactly does HEC improve the thickening effect and application properties of coatings?

1. How does HEC improve the thickening performance of coatings?

Hydroxyethyl cellulose is a type of water-soluble polymer thickener, and its thickening ability stems from its unique molecular structure and physical properties.

(1) Forms a three-dimensional network structure in water

After absorbing water and swelling, the long-chain molecules of HEC form hydrogen bonds with water molecules and entangle with other HEC molecular chains, thus building a stable three-dimensional network system.

This structure rapidly increases the viscosity of water-based coatings, making the system thicker and more stable.

Its effects include:

More uniform coating system

Particles are less likely to settle

Less likely to stratify during storage

Smoother feel and more even film formation during application

(2) Provides stable viscosity at different shear rates

HEC has excellent rheological control capabilities, maintaining reasonable viscosity at both low and high shear rates:

High viscosity at low shear → coating is less likely to sag

Moderate viscosity at high shear → smoother application

The thickening effect is more stable, without sudden thickening or thinning, resulting in a better experience for the applicator.

(3) Improves the storage stability of coatings

HEC can effectively prevent coatings from experiencing:

Stratification

Settling and hardening

Viscosity reduction

Color separation and mottling

Therefore, HEC is an indispensable thickener in many high-end latex paints and engineering paints.

2. How does HEC improve coating workability?

Workability is an important indicator of coating quality, directly affecting the application effect and user experience. HEC has advantages in improving workability.

(1) Improves the smoothness of brushing and rolling

HEC maintains suitable fluidity even under high shear conditions, making the coating:

Not stiff

Not sticky

Smooth to the touch

Easier for workers to apply, resulting in more even wall coverage.

(2) Improves leveling, reducing brush marks and roller marks

The rheological structure controlled by HEC allows the coating to self-level after application, effectively reducing:

Brush marks

Roller marks

Surface unevenness

Whether for interior or exterior wall coatings, a smoother film formation effect is achieved.

(3) Enhances the anti-sagging ability of the coating

During brushing, spraying, or thick coating applications, the coating may slide down or sag. HEC's ability to adjust high and low shear viscosity allows the coating to adhere firmly to the wall without sagging or dripping.

Suitable for:

Exterior wall coatings

High-coverage wall paints

Textured coatings

High PVC content engineering paints

(4) Reduces splashing during application

Roller splashing is a common problem with many water-based coatings.

HEC's thickening properties effectively reduce splashing during high-shear (roller) application, resulting in a cleaner work environment.

This is very important for both engineering construction and home renovation users:

Cleaner

More material-efficient

Reduced cleaning costs

(5) Optimizes the spraying process experience

In spray application, the coating needs to atomize evenly without excessive sagging. HEC stabilizes the flow characteristics of the coating, resulting in finer atomization and more even spraying.

3. What is the impact of different grades of HEC on coating performance?

Choosing the right HEC is crucial to achieving optimal thickening and application performance. Differences between different grades include:

Viscosity grade (low, medium, high)

Dissolution rate (standard type, fast-dissolving type)

Degree of substitution (affects stability and enzyme resistance)

For example:

High-viscosity HEC: Strong thickening ability, suitable for high-PVC coatings.

Medium-viscosity HEC: Combines fluidity and stability, suitable for general latex paints.

Fast-dissolving HEC: Less prone to clumping, suitable for rapid dispersion in factories.

Choosing different grades of HEC based on the formulation, solid content, and application requirements can achieve optimal performance for the coating.

Hydroxyethyl cellulose (HEC), as a thickening agent with stable performance, high thickening efficiency, and strong compatibility, plays a crucial role in water-based coatings. It not only significantly improves the viscosity and storage stability of the coating but also optimizes the application experience, resulting in smoother brushing, more even spraying, and a more aesthetically pleasing film.

简体中文

简体中文 English

English русский

русский عربى

عربى Español

Español